Brushless vs Brushed Motor for Drills — How Do They Differ?

It’s an issue that confuses DIYers and trade pros from Bunbury to Bundaberg — what’s the difference between brushed vs brushless motor power tools?

Although these two engineering formats are very close in design, for drill and boring unit users, it can lead to substantial differences in performance. And, depending on your project and personal requirements — either system could be correct for your needs.

This brushed motor versus brushless battle royale exposes the secrets of these two configurations — revealing what you, as a prospective drill purchaser, should consider in the best Australian drills, impact drivers, and saws.

Brushed vs Brushless — Down to the Tech

Before I get to the meat and compare brushless drill vs brushed machines and what it means for your jobs — a swift overview of the inside engineering will be beneficial. Mate, don’t be put off, it’s not very long and fairly interesting — if you’re struggling with it, crack open a tinny while reading, it’ll make it seem much more enjoyable.

The DC Brushed Motor

Let’s kick off this brushless vs brushed investigation with some serious wrongdoing.

In 1832, the Pommie scientist William Sturgeon invented the first-ever brushless motor. Being totally stoked about his creation, and having an air of arrogance like most poms, he told everyone he knew about his invention, its brilliance, how clever he was, and the way in which it operated.

Unfortunately, while Sturgo was phenomenal at self-promotion, he was lacking in the business head department — failing to apply for a patent for the technology. So, in 1837, Thomas Davenport — an American inventor — ‘borrowed’ the idea, ran down to the patent office, and claimed the invention as his own. A little bit of underhandedness that seems popular in the States, with Jobs and Edison doing the same things (allegedly).

Now, allow me to state the bl**dy obvious…

Brushed motors incorporate brushes. Brushless units don’t.

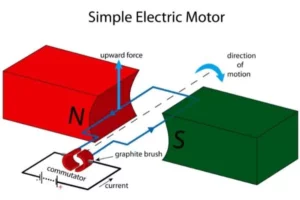

At the core of brushed-type motors are tightly wound coils of wire that encircle an armature. When electricity surges through these copper wires, they generate electromagnetic force. Surrounding the coils are twin stator permanent magnets with opposite polarity (identified as N and S in the previous picture).

Electricity penetrates the motor through graphite brushes (see image above). These brushes are in contact with a commutator — absorbing the current and directing it through to the coils.

Electromagnetic force drives the core in the opposite direction from the ‘N’ polarity, thus forcing it to turn. When the current reverses, the ‘S’ magnet polarity pushes away the rotor arm — having finished a complete circular turn. Naturally, this continuous repellence produces a spinning action — the foundation of all motors.

Here’s the key to remember — since the commutator finds itself attached to the crucial rotor arm, it also rotates. But, the brushes (touching it, not connected to it) stay stationary. Hence, these contacts are continuously vulnerable to heat and friction.

Already confused by my brushless vs brush motor? Check out this video of how a brushed motor works:

And, as a patriotic footnote, the first-ever electrical brushed motor boring machine was a rock-penetrating Australian drill, invented by the Melburnians William Blanch Brain and Arthur James Arnot in 1889. The poms are credited with nothing.

The DC Brushless Motor

Now let’s turn our attention in my brushed vs brushless motors exposé to the brushless system — called BLDC by techie pros — contrasts with its brushed sibling.

Early incarnations of this system were around in the nineteenth century, around the time of the first Australian gold rush. Unfortunately, they were gigantic — about the size of a car, so of little use in power tools. It was the invention of solid-state electronics about 70 years ago that permitted these units to become a practical size.

Now the detail — what is a brushless motor?

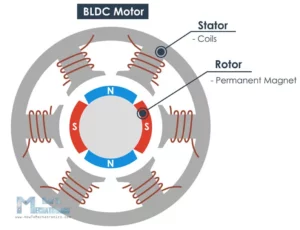

Akin to their similar brushed cousins, BLDC units also utilise electromagnetic attraction and repulsion — however, as indicated in the above image, their inside build differs.

Replacing the brushed motor’s brushes and commutator, in a BLDC, the stator rotates via electronic commutation. Bewildered? Crack open another cold one and then carry on reading.

Let me break it down.

In brushed motors, the magnets remain stationary, with the coil turning inside these components. As seen above, in a motor without brushes system, the coils are immobile and the magnets rotate.

Here’s the secret…

As the coils do not move, there’s no need for the motor’s brushes to distribute electricity to a turning stator. So, they’re brushless.

And, if despite reading the above thoroughly and you’re still no wiser — just watch this explanatory video:

What Is the Best — Brushless or Brushed Motors?

The juicy stuff in my brushed motor vs brushless motor face-off — what’s the ultimate system?

Sorry mate, I’m not going to give you a groundbreaking response. In truth, it just depends.

The Advantages and Disadvantages of Motors With Brushes

I know that your great Australian home is packed with brushed motors — in your aircon fan, cooking whisk, spray painter, vacuum cleaner, and kid’s toys.

Two reasons for this abundance — reliability and affordability.

With mass production efficiency and including minimal internal components, you can get your hands on a basic brushed motor for about an Aussie dollar. And naturally, low-cost parts mean a cheaper appliance. If there were to be a brush motor vs brushless motor price fight, the brushed format would be the winner.

Furthermore, since these components incorporate just a pair of magnets, a coil, a stator, brushes, and a commutator — there’s really nothing to go wrong.

However, if you’re an alert type of guy, it’s possible that you observed something in the list of appliances above — none of them are exposed to particularly high resistance or loads — meaning the motor doesn’t have to work that strenuously.

But challenge them with any kind of hard yakka — and they struggle. The biggest downfall of all brushed systems. And that’s where the brushless format takes over the mantle.

The Advantages and Disadvantages of Motors Without Brushes

When exposed to high forces, all motors with brushes are challenged by friction and heat — created by the brushes continually touching the spinning rotor. This leads to a rapid wearing of the commutator and the contacts — elevating the chance of breakdown and failure.

What’s more, these high-temperature levels, through conduction, pass into all the motor’s components — wrecking the internals and causing the external casing to become uncomfortably hot.

But, in brushless motors — as they have no brushes constantly in contact with the turning rotor — friction and heat are minimal. Thus increasing the longevity of the appliance.

Furthermore, as little energy is wasted due to heat and resistance, the brushless motor has greater efficiency than its brushed-format cousin. So, in real terms, when powered by an equal voltage and current — the motor without brushes will knock out a higher grunt and speed than a brushed system.

I know what’s on your mind — well, apart from beer and women.

You’re thinking to yourself, if brushless DCs are so amazing — why not consign the brushed version to history and include a brush-free format in every power tool?

The justifications are maintenance and cost.

Brushless DC motors are full of tech, a significant dependence on electronics (solid-state) means they cost some serious coin to manufacture and purchase.

And, although being low on friction, making them more reliable than brushed models — when they do fail — it’s going to be an expensive repair. Trust me, although any vaguely proficient DIYer can change the coil on a format that has brushes — you require impressive knowledge to fix an electronic-reliant system.

The Battle of Brushless vs Brush Drills

The big question — are drills without brushes better? You bet they are.

Here are the three most impressive advantages of utilising a brushless drill:

Minimal Maintenance

Lacking brushes subject to wear, nor internal parts suffering from significant heat exposure — brushless drills boast notably lengthy longevity. Chances are, the ratchet chuck will wear out earlier than the brushless powerhouse.

Minimal Vibration

The negligible friction concomitant to the motor of the brushless drill lessens handle and casing tremor — meaning a pleasing user experience, higher precision, and a reduction in hand and arm fatigue.

I’d suggest this is critical when wielding one of the best rotary or hammer drills in Australia — where the continual pummelling of tough masonry or concrete can place serious stress on your limbs and digits.

Impressive Efficiency

When looking at efficiency, asking is brushless motor better than brushed is a no-brainer. Yes, yes, and yes.

As there’s little wasted energy from heat and friction, you experience greater torque, brawn, and power with a brushless unit than you do with a drill with brushes — assuming the motor sizes are the same. And, although this is fantastic news for corded machines, for cordless, it’s even more crucial.

High efficiency leads to a lower power drain on the battery that drives the drill — meaning extended operational times — about fifty percent — as opposed to brushed models. In short, you can work for lengthier periods from one charge — hence minimal downtime switching batteries or recharging the lithium-ion cell.

Furthermore, in the non brushless vs brushless drill brawl, the brushless format outperforms the brushed due to:

- Higher torque to overall mass ratio.

- Minimal decibel operation.

- Eliminating the risk of commutator spark ionisation.

- Total removal of electromagnetic interference (EMI).

Drill Brushed vs Brushless — Time to Forget About Brushed Drills?

After you’ve consumed the above information on the non brushed vs brushless pros and cons — you’re probably thinking that the motors with brushes are pointless and should be avoided.

You don’t have to do that.

Admittedly, when you compare the best brushed drills vs brushless drill Australia has to offer, the former wins on efficiency, weight, vibration, noise, and maintenance. Yet, a Lamborghini is theoretically more impressive than a Toyota ute — but I’m guessing you don’t own an Italian sports car.

When choosing from a brushless or brush drill — it’s imperative you think about your preferences and the demands of your project.

Initially, the price. Contingent upon the model and make, brushless drills can be around 24-51 percent tougher on your Aussie dollars compared to brushed systems.

Then, I’d suggest the next step in opting for either a brushless drill vs brushed drill is to consider the efficiency. If you’ve already decided to go for a cordless model and long operational times are essential — then you undoubtedly need a machine without brushes.

But, should you be perfectly happy with a corded machine — or have no plans to continually drill for a period that exceeds 20 minutes or so with a cell model — the power efficiency of a brushless motor isn’t so important.

Finally, think about how much use and abuse you’re going to give your machine. When opting between a brushless vs drill brush unit, if you’re a high intensity or frequent user — go for a more durable brushless tool. Conversely, if you’re just a casual weekend user, the chances are you’re not going to put in the work hours to demand a massively robust drill.

Brushless vs Brushed Tools — The Conclusion

Making a decision between a brushed motor drill vs brushless motor is a crucial factor when selecting your new hole boring machine.

The brushless versions are the masters of pushing out higher efficiency, grunt, reliability, and operational times (for cordless models). But, these come at a more substantial price point, are tough to self-maintain, and the energy efficiency matters little on corded units.

Your ultimate drill for use in Australian homes and businesses means looking at the requirements of your jobs, the amount of cash you wish to spend, and your intensity of operation.

I seriously hope that you found my brushed motor vs brushless article helpful, interesting, and informative — and, if you know a mate that would also enjoy checking out this face-off, share with them!

The Brushed vs Brushless Motor FAQs

Brushless, What Does It Mean?

A motor that’s described as brushless indicates that the motor lacks brushes, which pass electricity to the commutator.

DeWalt Brushed Drill vs Brushless DeWalt Model Drill?

A drill from DeWalt that lacks brushes, for example, the lithium-cell DCD795M2, delivers long operational use because of its highly efficient motor format. The corded DeWalt DWD530KS possesses a motor with brushes, but as a mains-driven tool, the aspect of power efficiency is of minimal importance.

Brushless Drills, Are They Better?

If you need to decide between a brushed drill vs brushless drill, the superior system is dependent upon your requirements. Drills without brushes knockout greater reliability and efficiency, but they’re going to hit your hard-earned Australian dollars more significantly.

Brushless Drill — What Is It?

A drill with a motor without brushes removes the need for heat and friction-inducing brushes to provide electricity through to the crucial internal components. Conversely, they use spinning magnets inside fixed electromagnets.

Brushless Tools — Are They Better?

The main contrast between a brushed drill and a brushless drill — or to be fair also a brushed vs brushless impact driver — comes down to efficiency. With minimal friction and heat, brushless units knock out more impressive torque and speed when compared to their brushed counterparts (from an equally rated power source).

Brushless Motors — Are They Better?

As brushless motors create lower friction and heat than brushed models, they provide more efficiency and greater reliability.