A screwdriver bit is a tool for driving screws and one that can be fitted to most drilling power tools. All screws have a head with a contour such that an appropriate screwdriver tip can be engaged in it in such a way that the application of sufficient torque to the screwdriver will cause the screw to rotate.

Each screwdriver bit has different types of shanks and tips to suit different screws and applications – all are described in depth below.

Screwdriver Bit Styles

All screwdriver bits have what is known as a ¼” hex shank, and are able to fit into any drill with either a keyed, keyless, or ¼” (6.35mm) hex drive chuck. There are three styles of screwdriver bits available.

Insert Screwdriver Bits

Insert bits have an extremely short shank, cost the least out of all screwdriver bits, and are designed to clip into a magnetic bit holder.

Power Screwdriver Bits

Power bits are designed to fit straight into a drill’s chuck, but as they are of longer length, replacement costs are a little higher.

Double Ended Screwdriver Bits

Double ended bits feature a screwdriver bit on either end (either the same or different types). They can potentially give the screwdriver bit double the life of either an insert bit or a power bit at much less than double the cost. It is important to note though that due to the nature of their design they will not fit into a ¼” (6.35mm) hex drive chuck.

Milwaukee 50 Piece Impact Driver Bit Set Check Latest Price

Makita 42 Piece Impact-X Magnetic Driver Bit Set Check Latest Price

Kincrome K21010 81 Piece Magnetic Impact Driver Bit Set

Most Common Screw Driver Bit Types

There are many different types of screw driver bits available on the market, but here is an overview of the most common.

When using high-torque fastening tools like cordless impact drivers, it is important to purchase screwdriver bits that are rated for this type of use so as to ensure the bit’s longevity.

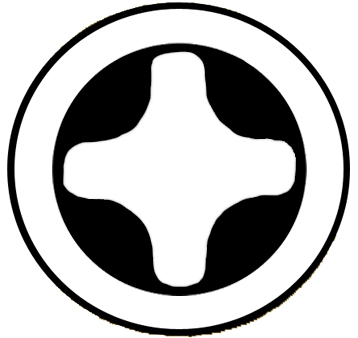

Phillips Bits

Phillips Bits

This is the most common type of screwdriver bit in Australia; mainly because they drive the most popular type of screw. Created by Henry F. Phillips, the Phillips screw driver was purposely designed to cam-out when the screw stalled, to prevent the fastener damaging the work or the head, instead damaging the driver. Philips bits look very much like a cross, and come in a range different sizes – #000, #00, #0, #1, #2, #3 and #4 (#2 is the most common). Check out Phillips Screwdriver Bits

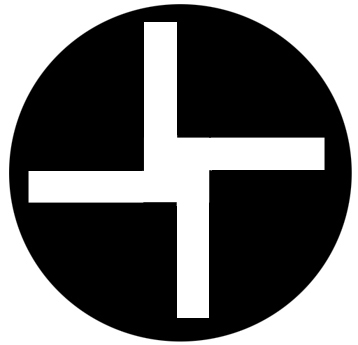

Pozidrive Bits

Pozidrive Bits

The Pozidrive screw driver is an improved version of the Phillips screw drive with an additional four contact points. These points decrease the likelihood the bit will cam-out, which allows greater torque to be applied. This design also provides a greater driving surface and decreases wear. They come in three main sizes – #1, #2 and #3 (#2 is again the most common).

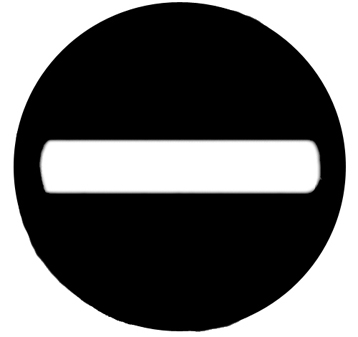

Slotted Bits

Slotted Bits

Slotted head screws aren’t very common anymore, but used to be the most popular type of screw available. Screwdriver tips are still made for them however, and the gauge of screw they drive defines their size. They aren’t often seen in applications where a power tool would be used however as the driver bit tends to slip out of the head and can potentially damage the surrounding material.

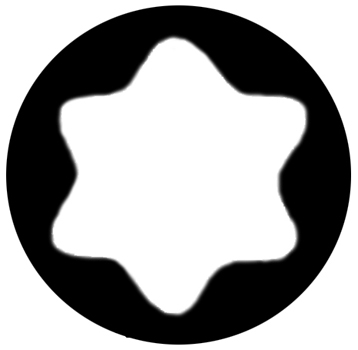

Torx Bits

Torx Bits

Torx bits are shaped like a 6-sided star and are used on anything from cars to consumer electronics. They resist cam-out better than Phillips or slotted bits, and were specifically designed with this purpose in mind due to the improvements in torque-limiting automatic screw driving tools. Sizes range from T1 through to T20.

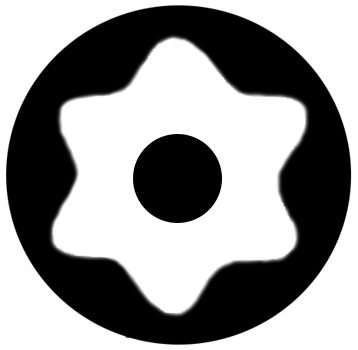

Tamperproof Torx Bits

Tamperproof Torx Bits

Tamperproof Torx Bits are a variant on standard torx bits. Instead of being solid, they have a hole in their centre to accommodate security screws, and to prevent the use of standard torx bits. They are generally used on anything that people don’t want you to have access to, and sizes again range from T1 to T20.

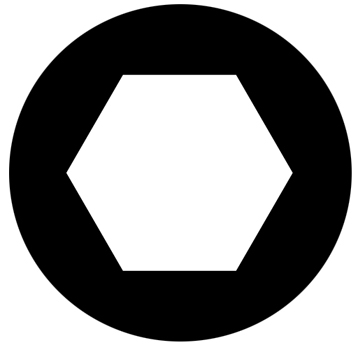

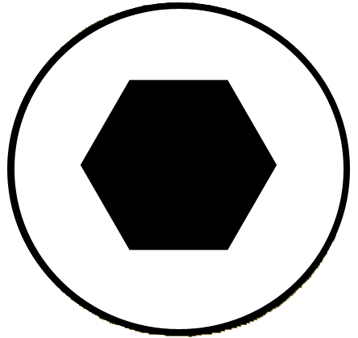

Internal Hex Bits

Internal Hex Bits

Basically an allen key that you can put in your drill, these hex bits are commonly used when assembling DIY furniture and for locations where surrounding obstacles limit allen key access. The standard size for most hex-drive screws is 5mm.

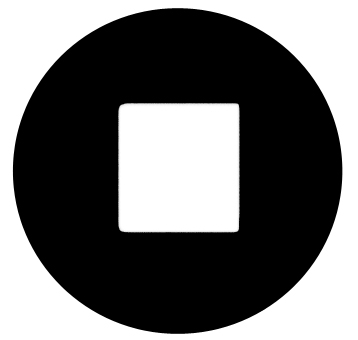

Square Recess Bits

Square Recess Bits

Square recess bits (also known as Robertson bits) were invented in 1908 by P.L. Robertson, a Canadian. The head has a slight taper which makes inserting the bit and keeping the screw on the bit a great deal easier. They are a lot more reliable than Phillips and slotted bits if you are trying to avoid cam-out, but in modern times are slowly being replaced by hex bits. These bits can be found in sizes #1, #2 and #3.

Nutsetters

Nutsetters

Nutsetters are similar to a hex bit, except they fit over their corresponding screws (in this case, tek-screws), rather than into them. They come in three main sizes – 1/4”, 5/16”, and 3/8”. Sometimes these sizes will be slightly small for the screw at hand. In this case, the nutsetter you require may be in metric (i.e. instead of a 3/8” (9.38mm) nutsetter, you may need a 10mm). They are ideal for handling the torque on applications where impact drivers are used.

Drywall Bits

Drywall Bits

Drywall bits are phillips screwdriver bits with a metal ring around them. This ring sits just below the end of the phillips bit and upon screw driving, the ring presses up against the material and stops the screw from being driven below the material’s surface.

Torq Bits

Torq Bits

Torq bits are very similar to phillips bits, but each arm of it’s cross-like shape is offset from it’s opposite. It is a tamper-resistant style of screw drive, and is most frequently used for aerospace applications.

Tri-Wing Bits

Tri-Wing Bits

As the name suggests, Tri-Wing bits have three evenly spaced slots and are predominantly used on consumer electronics to discourage home repair. They are available in sizes #1 through to #4.

Spanner Bits

Spanner Bits

Also known as “Snake Eyes,” Spanner Bits fit into their respective screws via two small round symmetrical pins. They are security bits, and come in sizes #4, #6, #8 and #10.

Tri-Lobular Bits

Tri-Lobular Bits

Tri-Lobular Bits are also known as TP3® Bits, and are becoming increasingly common on consumer electronics, security doors and many other tamper-proof applications.

Screwdriver Socket Adaptors

Socket adaptors give you the ability to attach sockets to a drill, allowing you to tighten nuts or screws that are too big for nutsetters. In order to fit most size sockets, they are available in the main three drive sizes – 1/4”, 3/8“, and 1/2”.

Manufacturer’s warranties do not cover the misuse or abuse of sockets, and if your socket fractures as a result of use in a power tool, it is considered misuse. Special sockets called impact sockets are available for high torque fastening applications.

Milwaukee 50 Piece Impact Driver Bit Set Check Latest Price

Makita 42 Piece Impact-X Magnetic Driver Bit Set Check Latest Price

Kincrome K21010 81 Piece Magnetic Impact Driver Bit Set

Screw Driver Bit Operating Tips

The following tips will preserve the life of your screws and screw driver bits, and will also increase your efficiency.

- To prevent slipping and/or stripping of the screw head, apply ample pressure to the bit and keep it perfectly in-line with the screw.

- It is ideal to have a drill with a variable speed trigger, as it is extremely helpful for an accuracy standpoint if your drill can reach very slow speeds.

- A power tool with a clutch (such as a cordless screwdriver or a cordless drill) is even better, as you can preselect the driving depth.

Personal protective equipment (PPE) must always be worn when operating power tools. For more information on PPE and power tool safety, click here.

Was this guide helpful? Has anything been left out? Are there any improvements that could be made? Please take a moment of your time and click here to provide your valuable feedback.