The Best Circular Saws Australia, Information, Buyers Guides, Comparisons and Reviews

– Circular Saw Features

– Circular Saw Blades

– Best Circular Saw To Buy

– Circular Saw Operating Tips

Circular saws are robust and powerful electric power tools. Their name (commonly shortened to ‘circ saws’ or ‘Skil saws’) is derived from the circular motion of a rapidly spinning steel toothed blade they use to perform accurate, fast and straight cuts in wood. These cuts are usually defined as either cross cuts (across the grain of the wood), rip cuts (along the grain of the wood), or bevel cuts (cuts where the blade is on an angle). With careful blade selection, they may also be used for aluminium, plastics and fibre cement.

Circular saws are categorised by the diameter of the blade they use (the measurement across the blade, or the distance from one side to another). The larger the diameter of the circular saw blade, the deeper the saw is able to cut.

There are five main circular saw sizes available in Australia:

160mm (6 ¼“)

185mm (7 ¼”)

210mm (8 ¼”)

235mm (9 ¼”)

270mm (10 ½”)

The two most common and popular sizes are 185mm (7 ¼”) and 235mm (9 ¼”).

For the professionals out there, or the very savvy DIY’ers with deep pockets, some manufacturers also produce plunge cutting circular saws. These saws are spring-loaded and can ‘drop in’ on your work. They create a splinter free finish and usually come with guide rails that they run along, improving their accuracy ten-fold.

Circular Saw Features

Circular saws feature many different components, and having a sound understanding of these plays an important part in choosing the best circular saw for you. Knowledge of these parts also aids in the efficient and effective use of the tool.

Circular Saw Power Source

The power source is the component that provides the tool with electricity. On circular saws, this is done through a wired connection to a mains power supply. In Australia, circular saws operate off mains power (240V) through a 10A socket.

Cordless circular saws that are powered by a battery and a charger are also available and bear very similar features to those described below. They are generally not as powerful as their corded equivalents, have smaller diameter blades, and require regular charging. They are however considerably light in weight and are the best circular saws if portability is paramount. Nearly all cordless circular saws also have the blade positioned on the other side (one of the only manufacturers that doesn’t do this is AEG).

Circular Saw Switch

The switch allows the electricity from the power source to flow through the tool. A circular saw is activated by a trigger switch. When the trigger is depressed, the tool will begin to operate.

Circular Saw Motors

Motors are the main component of all power tools, and are the component that converts the electricity into motion. The power that motors produce is measured in Watts. otors used in corded circular saws are called AC motors (they are also known as universal or series motors).

Depending on the model, circular saws can have motors with up to 2100W of input power, and can weigh anywhere between 3 and 8kg.

Many manufacturers will state only the input power of the saw, as this is the larger and more impressive number. This value is actually just an indication of the demand a tool will place on a power outlet under normal operating conditions. The power output at the blade, though, is significantly less than the input power. This is due to the efficiency of the saw’s internal components, and how power is transferred through the machine. Generally speaking, higher quality tools and the best circular saws have greater efficiency and require less input power to produce the same power output. Therefore, although it is uncommon for most manufacturers to include a power output value, it is a much better way of comparing tools. With circular saws, the best indication of power is wattage, as speed is constant.

Most professional quality tools will have a round port on either side of their housing. These ports give simple access (with a slotted screwdriver) to the most frequently wearing component of any tool – it’s brushes.

The best circular saws will also feature an electric brake. This brings the blade to a stop as soon as the switch is released, giving you more time to prepare for your next cut whilst still maintaining a safe work environment.

Circular Saw Transmission

Also known as a gearbox, a transmission dictates the speed that a circular saw operates at. These speeds are usually between about 4000rpm and 6000rpm. These values are the maximum speed the saws attain, and are reached after an initial acceleration phase.

Transmissions also dictate (to an extent) the power a circular saw outputs. The best circular saws have helical gears in their transmission that are capable of producing far more torque (turning force) than other units.

Circular Saw Lock Nut System

The lock nut system refers to the components of a circular saw that hold the blade in place. The system is made up of an inner flange, an outer flange, and a hex bolt (generally). The hex bolt is fastened into place by an included spanner or allen key.

During a blade change, only the hex bolt and the outer flange need to be removed. The blade should be rigidly secured onto the saw before the tool is used.

Circular Saw Shaft Lock Lever

To mount and remove a circular saw blade, the machine’s drive shaft must remain stationary. This is done through the use of a shaft lock lever. Once this lever is engaged it locks the shaft into position, and allows you to loosen/tighten the hex bolt (in the lock nut system).

When pressing the lock lever, the shaft will not instantaneously lock in that position. You just need to rotate the blade/shaft a little and it will fall into a locked position.

Some circular saws do not have this lever. In this case, to remove the blade from the saw, jiggle the saw blade back and forth in short, swift motions with your hand (the use of gloves is advised). These motions will loosen the lock nut, and you will subsequently be able to remove the saw blade. To mount the saw blade, simply fit the outer flange in place and tighten the hex bolt until the saw’s shaft begins to move.

Circular Saw Bevel Lever

The bevel lever holds the saw blade at a set angle for cutting. When this lever is disengaged, the circular saw is free to move between its default vertical position (0°) to an angle of up to 45°.

Some circular saws may be able to cut on angles of up to 56° (from the vertical).

Circular Saw Riving Knife

Upon cutting wood, it will tend to want to close back together. To stop this from happening around the blade, a riving knife is employed. This component is a thin piece of metal located just behind the blade, and is a safety measure found on nearly all circular saws.

Circular Saw Housing

Housings on circular saws are made from a combination of plastic and metal.

The most important part of the housing is the protective guard. This is the component that houses the spinning blade, and the wood chips that go with it. It is generally made of thick die cast aluminium or metal for safety reasons. The upper section of this guard is fixed, and the lower will move out of the way by itself when cutting commences. It must however be pulled back manually when changing a blade.

Some circular saws can project a laser line from their housing along a pre-marked cutting line to increase the accuracy of cuts. Others may also have an LED light at their front that light up the work upon operation of the tool.

Some circular saws can project a laser line from their housing along a pre-marked cutting line to increase the accuracy of cuts. Others may also have an LED light at their front that light up the work upon operation of the tool.

Circular Saw Handle

The handle is the where your right hand must be positioned. This is the hand that operates the tool’s switch, and is also the point where you can apply the most forward pressure.

Circular Saw Support Handle

The support handle is where your left hand must be placed, and is the component of circular saws that gives you the necessary stability to make an accurate and safe cut.

Circular Saw Base Plate

The base plate of a circular saw is the plate that rests on the material and provides stability as cutting occurs. It can be made from steel (low cost and very durable) or aluminium (more precise, but more expensive and easier to damage).

On circular saws, the base plate adjusts the depth of the cut. This is adjusted by loosening a small lever to the rear of the saw, and pulling the base plate up or down.

On circular saws, the base plate adjusts the depth of the cut. This is adjusted by loosening a small lever to the rear of the saw, and pulling the base plate up or down.

On most circular saws, the base plate will have two cut outs at its top that you can use as a guide when following a cutting line you have drawn on the material. One is for 90° cutting, and the other is for 45° cutting.

How deep the circular saw can cut is determined by the particular model of circular saw and the diameter of it’s blade. The maximum cutting depths that each size circular saw has at both 0° and 45° are illustrated below.

| Blade Size | 0° | 45° |

|---|---|---|

| 160mm (6¼“) | 55mm | 36mm |

| 185mm (7¼”) | 65mm | 46mm |

| 210mm (8¼”) | 76mm | 57mm |

| 235mm (9¼”) | 87mm | 60mm |

| 270mm (10½”) | 100mm | 73mm |

These maximum cutting capacities depend on the specific model of the circular saw, and it is recommended that you consult these specifics before making a purchase.

Circular Saw Chip Chute

The chip chute is integrated into the protective guard. It directs sawdust and wood chips out of the tool and away from you, and is found on all circular saws.

Circular Saw Parallel Guide

A parallel guide is used to guide a circular saw along the length of a desired material parallel with its edge (i.e. a rip cut). It runs through the base plate of the tool, is easily adjustable to the width required, and is found on nearly all circular saws.

A parallel guide is used to guide a circular saw along the length of a desired material parallel with its edge (i.e. a rip cut). It runs through the base plate of the tool, is easily adjustable to the width required, and is found on nearly all circular saws.

With a bit of careful measurement, a straight piece of wood/metal (straight edge or guide batten) clamped down along the material being cut can serve the same purpose. It will allow the circular saw to run along its edge, sawing through the material along the angle you have set. It is also the best alternative if you are making a cut further away than the parallel guide will allow.

Circular Saw Blades

The blade that a circular saw uses is the key characteristic that defines its cutting capabilities, and is the tool’s primary accessory.

Always ensure the tool is disconnected from the power source prior to changing accessories. For more safety recommendations, click here.

There are many different types of saw blades available, and each one has their own strengths and weaknesses. This means there is a little more to picking the best circular saw blade for your job than simply matching up dimensions.

To choose a blade for your circular saw, you must know the blade diameter and the bore diameter first.

Circular Saw Bore Diameter

The bore diameter of any blade refers to the size of the hole in its centre. This size corresponds to the shaft size of the saw, and is something that varies between power tool manufacturers and models. The most common sizes are 16mm, 19mm, 20mm, 25mm and 30mm.

The bore diameter of any blade refers to the size of the hole in its centre. This size corresponds to the shaft size of the saw, and is something that varies between power tool manufacturers and models. The most common sizes are 16mm, 19mm, 20mm, 25mm and 30mm.

To reduce confusion, all the best circular saw blade manufacturers produce blades with the largest diameter bores probable on that size blade, and include bushes in the saw blade packaging to reduce this hole to a smaller size (if need be).

The bushes can fitted over the tool’s drive shaft onto the blade. As the outer flange and hex bolt are tightened, the bush is pressed into the centre of the blade, providing a rigid and secure fitment for the blade. It is a good idea to check that the bush has actually been pressed into the blade before starting up the machine. You can also use a mallet to tap the bush into the bore of the blade (before it is put on the machine).

Circular Saw Blade Types

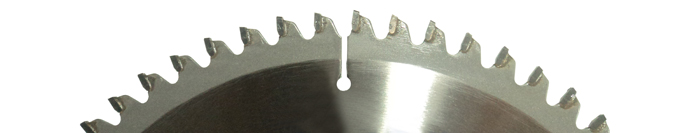

Circular saw blades are all made out of steel, but it is the teeth that cut the material and also define the quality of the blade.

There are two main types of circular saw blades – steel tipped blades and tungsten carbide tipped blades.

Steel tipped blades are the cheapest style but wear at a high rate. This means they must be sharpened often if used regularly.

The best circular saw blades are those tipped with tungsten carbide. They do cost a little bit more, but are far more durable, lasting up to 50 times longer than steel tipped blades.

It is recommended that you use gloves when handling saw blades. They are very sharp, can easily give break the skin, and also get very hot after use. Always use clean, sharp blades. If you can tightly grab a blade, chances are it needs replacing or resharpening. For more safety recommendations, click here.

There are a range of saw blades for different types of materials and applications. These materials include wood, aluminium, plastics, and fibre cement.

A wood cutting blade is only able to cut wood, has quite aggressive angled teeth, and requires minimal effort from the saw for maximum effectiveness. Some wood cutting blades will have alternatively offset teeth that act like small shaving knives, allowing them to effectively cut laminated wood without damaging the laminate surface.

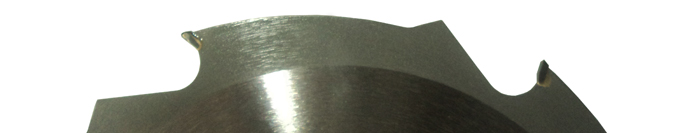

Aluminium cutting blades have lots of negative hook teeth that allow them to power through aluminium, plastics, and wood. Though not as fast as wood cutting blades, this less aggressive style of blade stays sharper for longer, mainly due to the better edge retention characteristics of it’s teeth.

Fibre cement cutting blades have a very unique design, featuring only 6 teeth, and are capable of cutting fibre cement products such as Hardiflex®, Hardipanel®, and Villaboard®. They are also suitable for wood, but cannot cut through compressed fibre cement flooring.

Abrasive blades (used on angle grinders to cut metal and masonry) are not designed for use on a circular saw. Circular saws run at a slower speed than angle grinders, facilitating the blade to catch and shatter. Circular saws are not equipped with the correct safety guards to protect you against an exploding cutting wheel either. Also, if you are cutting masonry, the dust from the material will get into the saw’s motor and bearings and you will more than likely be up for a brand new saw.

The finish of the cut is predominantly dictated by the number of teeth on the blade, a number ranging from 16T to 120T (depending on the diameter and purpose of the blade).

The finish of the cut is predominantly dictated by the number of teeth on the blade, a number ranging from 16T to 120T (depending on the diameter and purpose of the blade).

As a general rule, the harder the material, the more teeth you require. And the more teeth you have, the cleaner the cut will be, but the longer the cut will take to perform.

Saw blades with a low tooth count are designed for both rip and cross cutting and are most effective when used on thick materials. Those with a high tooth count on the other hand are designed only for cross cutting, and are the best circular saw blades for cutting thin materials.

Saw blades with a low tooth count are designed for both rip and cross cutting and are most effective when used on thick materials. Those with a high tooth count on the other hand are designed only for cross cutting, and are the best circular saw blades for cutting thin materials.

The cutting width of a blade is referred to as the ‘kerf’ of the blade. Blades with a thin kerf cut faster, finer, and reduce the load placed on the saw’s motor.

Most blades will also have small slits known as expansion slots in them, that create an outlet for heat and prevent the blade from warping.

Best Circular Saw To Buy in Australia

Best Cordless 185mm Circular Saws

Makita 235mm Cordless Circular Saws

When purchasing the best circular saw for you, decide what features are most important to you (from the specifications above) and make sure these are included in your final purchase. The main considerations you should make include how much power you require, the size and weight of the tool, whether you need it to be cordless, and how often you will be using it.

Look for a robust and durable circular saw that has plenty of high quality components. Also, make sure you ‘weigh up’ the cutting capacity of the saw versus its weight. After all, the larger the blade of a circular saw, the larger the motor that it needs to drive it, and that means a significant increase in weight.

Manufacturers will either direct their products at the DIY or professional market. DIY tools are designed for home use and generally include plenty of features for a very modest price. They also tend to have very generous warranty periods, including replacement warranties. Professional tools are designed for commercial use and are built for durability, performance, and reliability. Their warranty periods tend to be much shorter than DIY tools, and are exclusively repair warranties. The main advantage of these tools is that they should well outlive their warranty period, and if they require repair and maintenance spare parts are readily available.

The price of any tool will depend on the quality, capabilities, and features of the model. Bear in mind that at least one of these three elements is commonly sacrificed by manufacturers to reduce the tool’s price and increase its sales. After all, price is the most important factor for consumers.

Circular saws can cost anywhere from $40 to $800.

Plunge cutting circular saws can cost up to $1300.

It is important to bear in mind that the entire cost of any power tool is not just it’s initial purchase cost. Added costs can include accessories for the tool to function, maintenance, downtime, and replacement costs. Buying according to your requirements will help to keep these costs to a minimum.

To browse manufacturers of circular saws, please select a company from our list of power tool manufacturers.

Circular Saw Operating Tips

The following tips will help to preserve the life of your circular saw, increase your efficiency, and most importantly, keep you safe. They will also give you the best circular saw cuts possible.

- Never apply excessive forward pressure to the saw when cutting- always let the blade do the work. The saw should be pushed forward at a speed so the blade cuts without slowing.

- Always ensure blades are sharp to ensure less load on the tool and better cutting results.

- Always allow the machine to reach its full speed for you begin cutting.

- For safest operation and best cutting results, lower the blade so it only penetrates the material being cut by 5mm. This will reduce the likelihood of kickback (when the saw jumps out of the wood), and will use the blade’s teeth in the most efficient manner.

- To further prevent blade kickback, support the board or panel near the cut, and never attempt to remove the saw from the work or pull the saw backward while the blade is in motion.

- Always operate the saw with two hands and when positioned in a firm stance. Be sure to position your body on either side of the blade but not in line with it.

- Use extra caution when cutting damp wood, pressure treated timber, wood containing knots, or wood with nails in it.

- Always position the wider portion of the base plate on the part of the work which will stay supported, and not the section that will fall away once the cut is made.

- Always make sure all levers and knobs are tightly secured.

- To obtain clean cuts, keep the sawing line straight and move the saw at a uniform pace.

Personal protective equipment (PPE) must always be worn when operating power tools. For more information on PPE and power tool safety.

Was this guide helpful? Has anything been left out? Are there any improvements that could be made? Please take a moment of your time and click here to provide your valuable feedback.